Are you planning the expansion, new construction or renewal of your steam plant?

We deliver turn-key steam boiler systems including the appropriate steam boiler

From 10kg/h to 50,000kg/h of steam: From the smallest system, which Aerni AG manufactures in its own workshops, to large systems, we can provide you with expert service. We cover steam systems with large capacity water boilers, high speed steam generators and electric steam generators. We can also supply them in containers or as fully mobile systems. Whether you need high pressure, low pressure or pure steam.

We offer you everything from a single source: technical advice, engineering, schematic design, realisation and maintenance / service. You can rely on detailed advice, competent fitters and certified welders.

Benefit from our experience and choose a standardised steam system from our steam system portfolio.

Advantages with Aerni

You will benefit from working with us as follows:

Steam plant from a single source

You do not need a design or engineering office, you receive the design, including P&I diagram and 3D plan, directly from us.

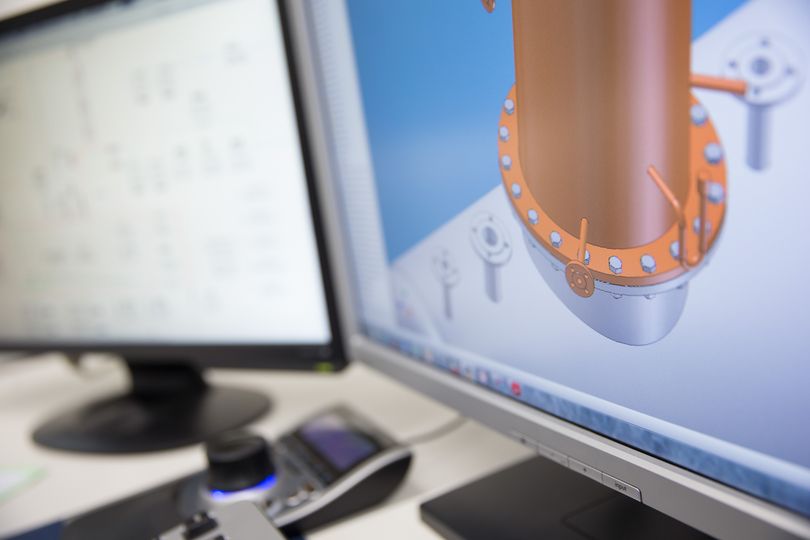

Digital image

We scan your premises and design the entire system digitally. This allows you to inspect your system in advance and incorporate adjustments.

In-house production/short implementation time

We prefabricate the majority of the steam system in our workshops. This is more efficient and takes less time, which ultimately benefits you in terms of price.

Service Packages

Depending on the steam expertise of your team and the size of your steam system and pipework network, you can outsource steam-related tasks to us.

One point of contact

We can help you set up new systems, manage existing systems, relocate, service, spare parts, control and maintenance. No more dealing with other parties, we do it for you.

50+ years of steam expertise

We have been involved with steam for over 50 years and know how systems work - and when it 'hits' once, why not.

Benefit from our experience and choose a steam system from our steam system portfolio

Based on your requirements, we develop a customised steam system that is largely based on tried-and-tested systems, in line with our motto.

"Every installation a matching unique, but 90% standardized!"

Therefore, you are benefiting of a system with a low standard price and get the advantage of a customized steam boiler system boosting your effectivity.

Our Process

Consultation + Selection

We determine the most suitable steam system according to your requirements, the steam consumption profile and the local conditions. You will then receive a quotation for the entire system, from the boiler house to the connection to the steam consumers.

Spacial Scan + 3D Image

After selecting the steam boiler system, we scan the premises on site. From this, we digitally design your finished steam system and can take pipe routing and interfaces into account at an early stage.

Production + Installation

We prefabricate tanks, pipework and other components in our workshops.

We will then install the system at your site within a short implementation period and connect it to the required steam consumers.Commissioning

Finally, we will commission the steam system and have it approved by the relevant authorities (SVTI) on your behalf. If you choose our service package, the system is seamlessly handed over to our service department.

Our Portfolio:

From shell boilers, to rapid steam generators, to electric steam generators

We are happy to offer you solutions according to your needs

Do you have a steam consumption profile with many consumption peaks? Do you need large quantities of steam within a few minutes? Then we will be happy to help you with our steam systems based on industrial hot water boiler systems.

You need only small quantities of steam? We build and supply in-house manufactured electric steam generators from 38-100kW. You do not need any approval or large piping. Above 100kW, we work with our competent partners to produce larger quantities of steam electrically.

You need constant high temperatures up to 350° degrees? You want the entire system to be pressure-free and low-maintenance? We would be happy to offer you our systems with thermal oil heaters.

Engineering and manufacturing

A short text or sketch is sufficient for us to make you an offer for the design and manufacture of the container.

We are happy to manufacture according to your dimensions or your drawing. You can also benefit from steam tanks that can be customized for you at a reasonable price.

Our specialities are vessels which are used in steam plants such as feed water vessels, condensate collecting vessels, mixing coolers, steam distributors, and others. We are happy to build heat recovery capabilities into or onto the vessels.

Operating Service

You would like to focus on your core business and preferably have nothing to do with your steam boiler system? You actually only want steam, the system is a necessary obligation?

We are pleased to offer you our operating service. Depending on your wishes, we can support you with the annual work or completely take over the operation of your steam plant.

Steam lending system

You have a planned or unplanned interruption in your steam supply. We can react immediately.With rental plants from 50kg/h to 6'000kg/h we secure your steam supply.

Aerni connects:

Steam expertise

Not all pipework is the same. Steam pipework requires expansion spaces and the inclusion of gradients so that your system functions smoothly in the end.

Internal Devices

The majority of our cables is manufactured in-house. Our more efficient machinery enables us to offer our products at lower prices.

Short Assembly Periods

Internal pre-setting and digital construction site recording ensure the smallest possible assembly window. This means you have shorter production interruptions.

Contact us for a no obligation viewing appointment

We will convince you with the right management and a competitive offer.